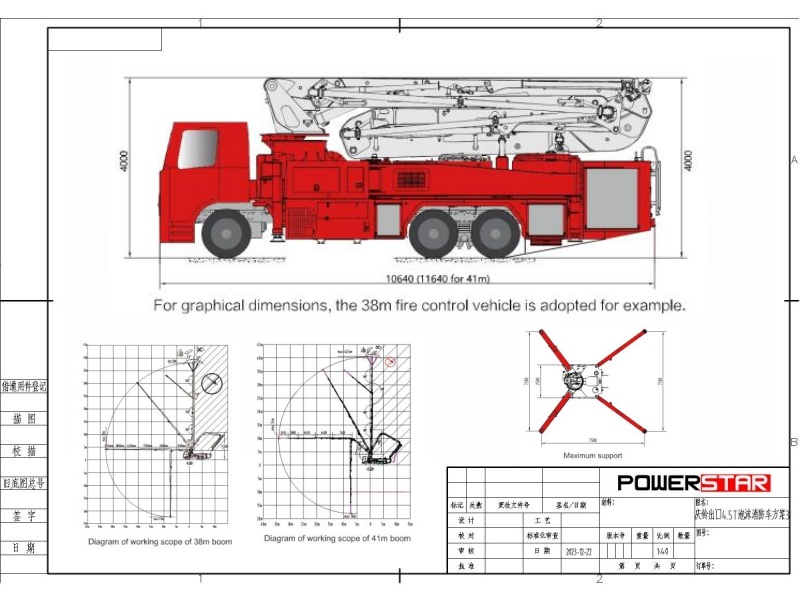

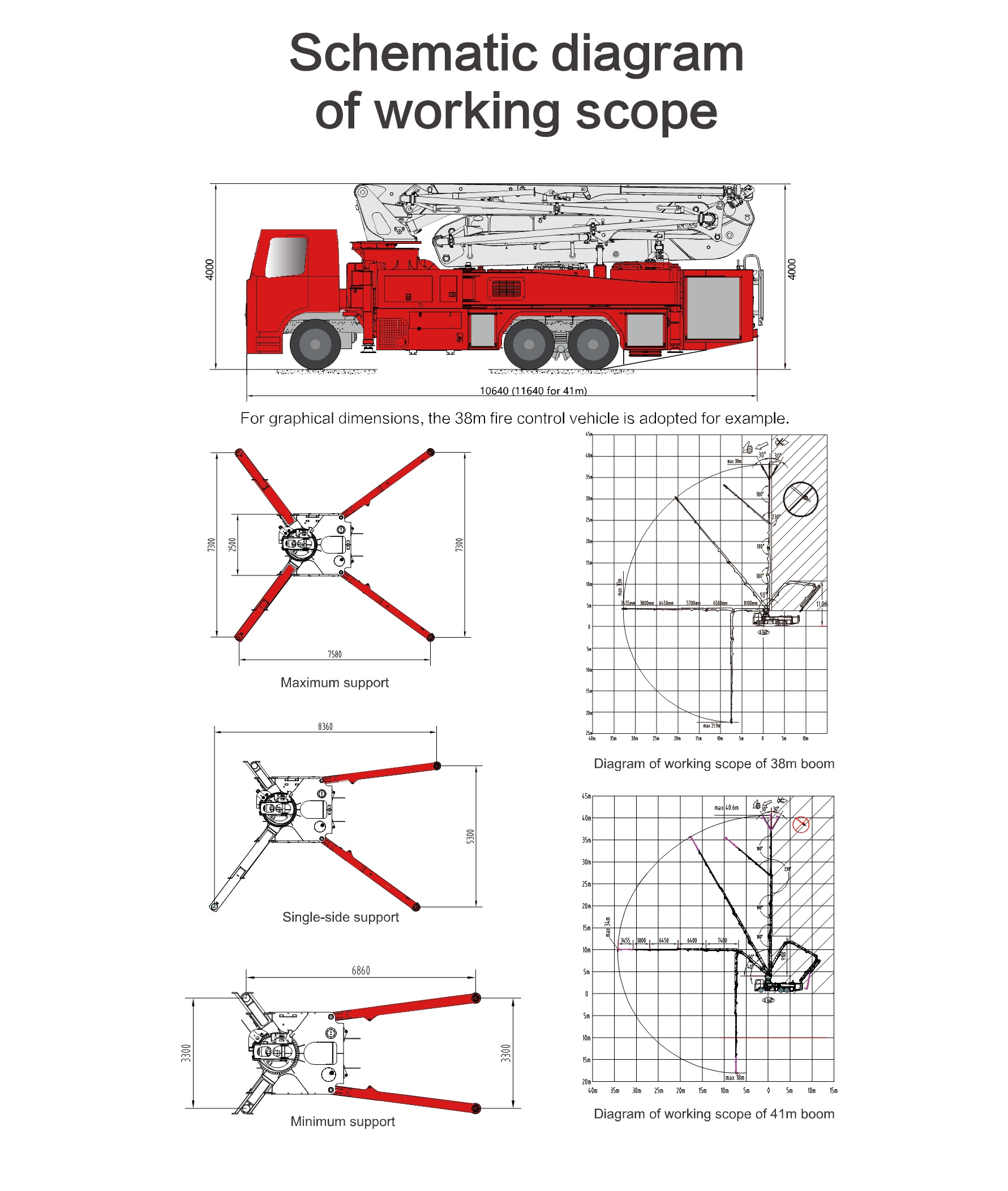

The technical design drawings of the 38-meter aerial fire truck cover several key parts such as the vehicle structure, hydraulic system, electrical system, jet system and safety design, ensuring the vehicle's efficient, flexible and safe operation in complex fire scenes. Through continuous technological innovation and optimization, the 38-meter high-lift jet fire truck will play a more important role in future firefighting and rescue.

The Isuzu Giga 38-meter aerial fire truck is a fire-fighting equipment specially used for fire rescue in high-rise buildings, large-span spaces, petrochemicals, etc. Adopt Isuzu GIGA 6x4 or 8x4 cab truck chassis, FAST 12-shift gearbox, special for fire fighting appliction. Its core function is to raise the fire cannon or jet device to a height of 38 meters by raising the boom to achieve long-distance and accurate firefighting operations. This model is mainly composed of a folding telescopic arm structure, an electric remote-controlled fire cannon, a tank body and a second-class chassis. The boom is usually a multi-section telescopic design (such as a two-section arm, a three-section arm or a four-section arm), and an electronic remote-controlled fire cannon is installed at the end of the arm. Firefighters can flexibly adjust the spray angle at high altitudes through an electric remote control device to perform firefighting operations such as spraying, water spraying or foam spraying.

The telescopic movement of its boom is synchronized by a hydraulic cylinder, chain and guide wheel. The fire hose is fixed on one side of the telescopic arm and is telescoped and raised with the boom. The operator can control the telescopic and rotation of the boom through the electric control handle on the turntable to ensure the flexibility and efficiency of the firefighting operation. In addition, the 38-meter high-rise jet fire truck also has the ability to operate over a very long span, and can achieve three-dimensional coordinated operations and ultra-close pinpoint firefighting. It is suitable for complex fire scenes such as high-rise buildings, large-span spaces, and petrochemicals.

The following is a detailed analysis of its technical design drawings.

1. Vehicle structure design

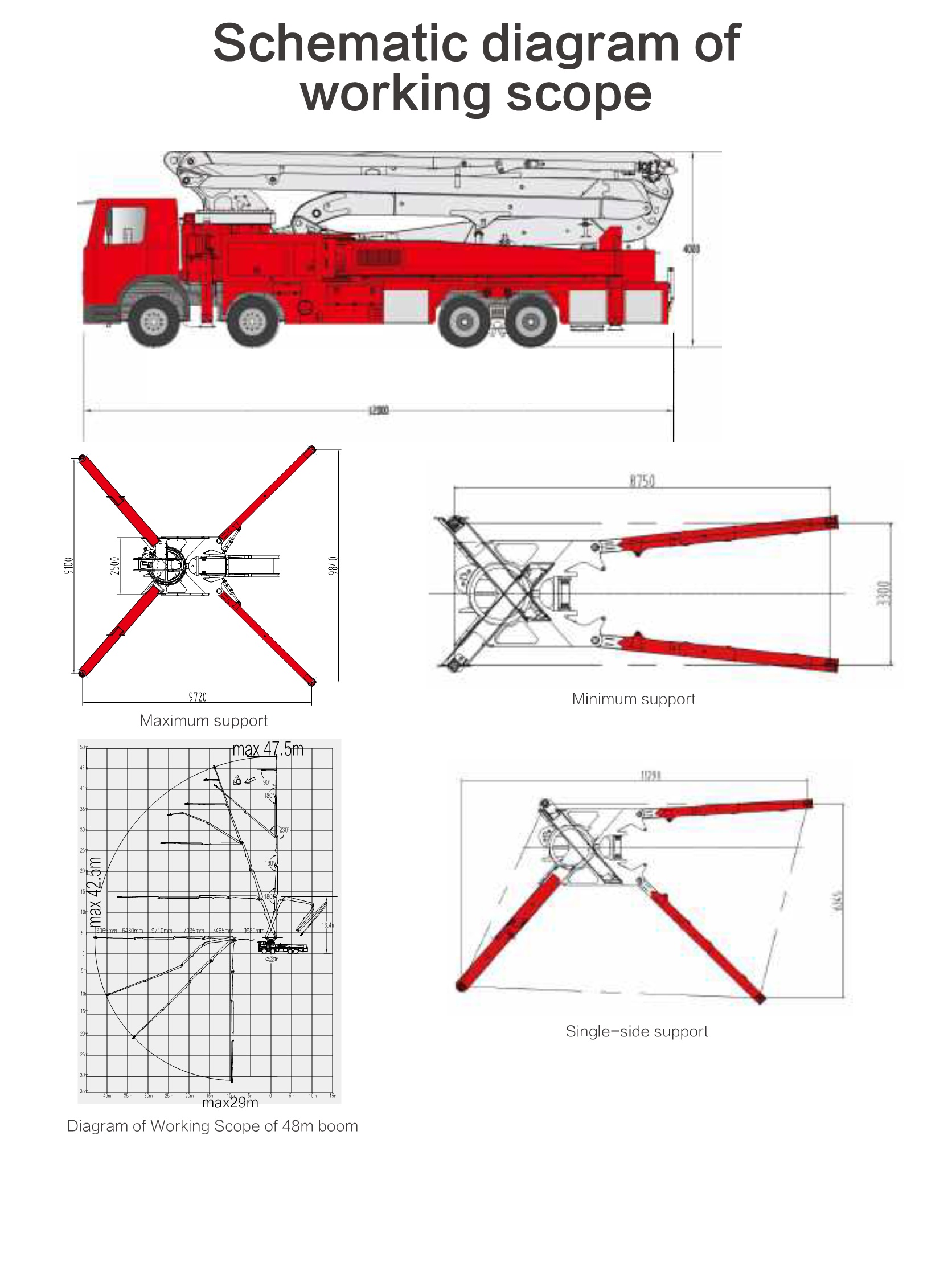

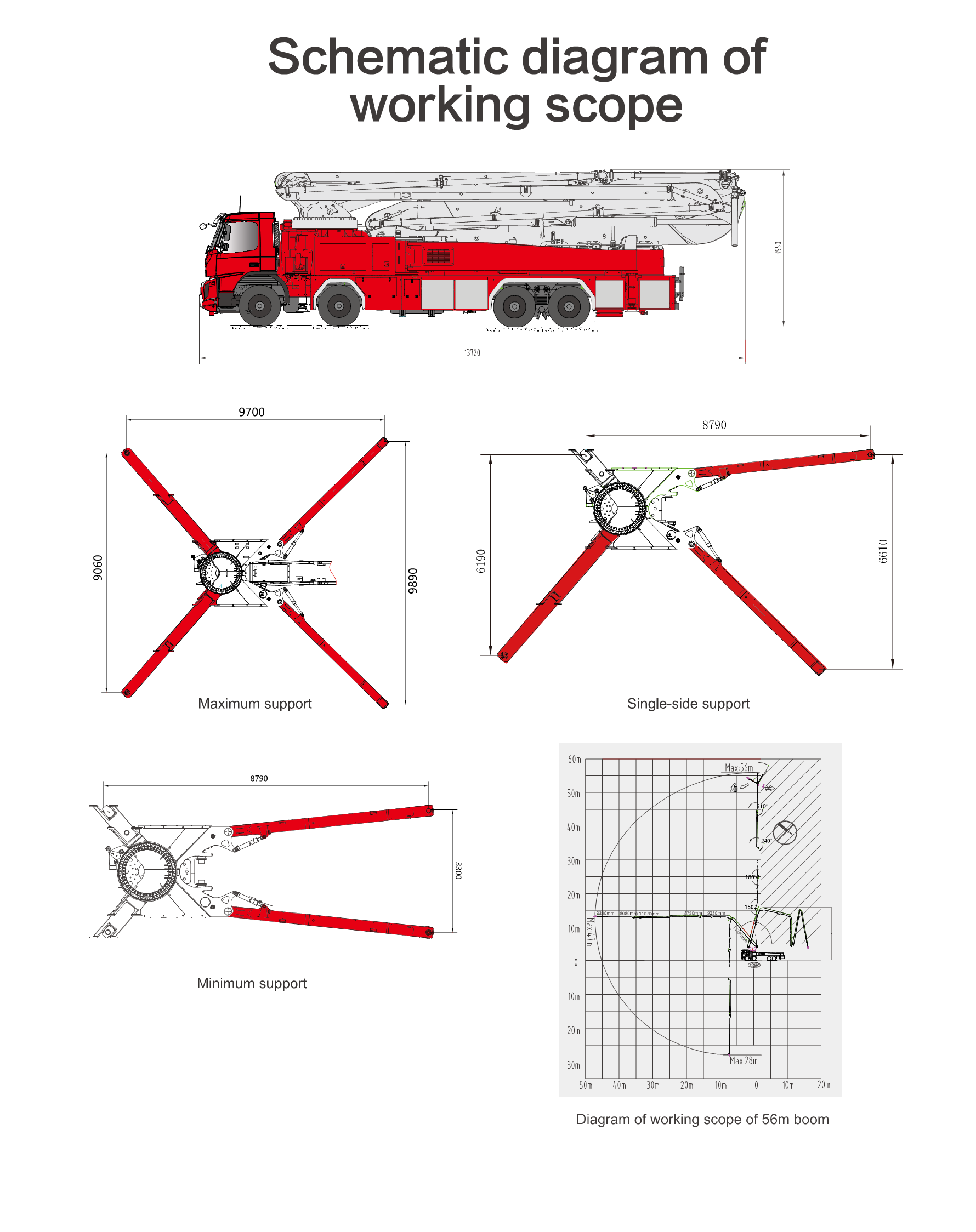

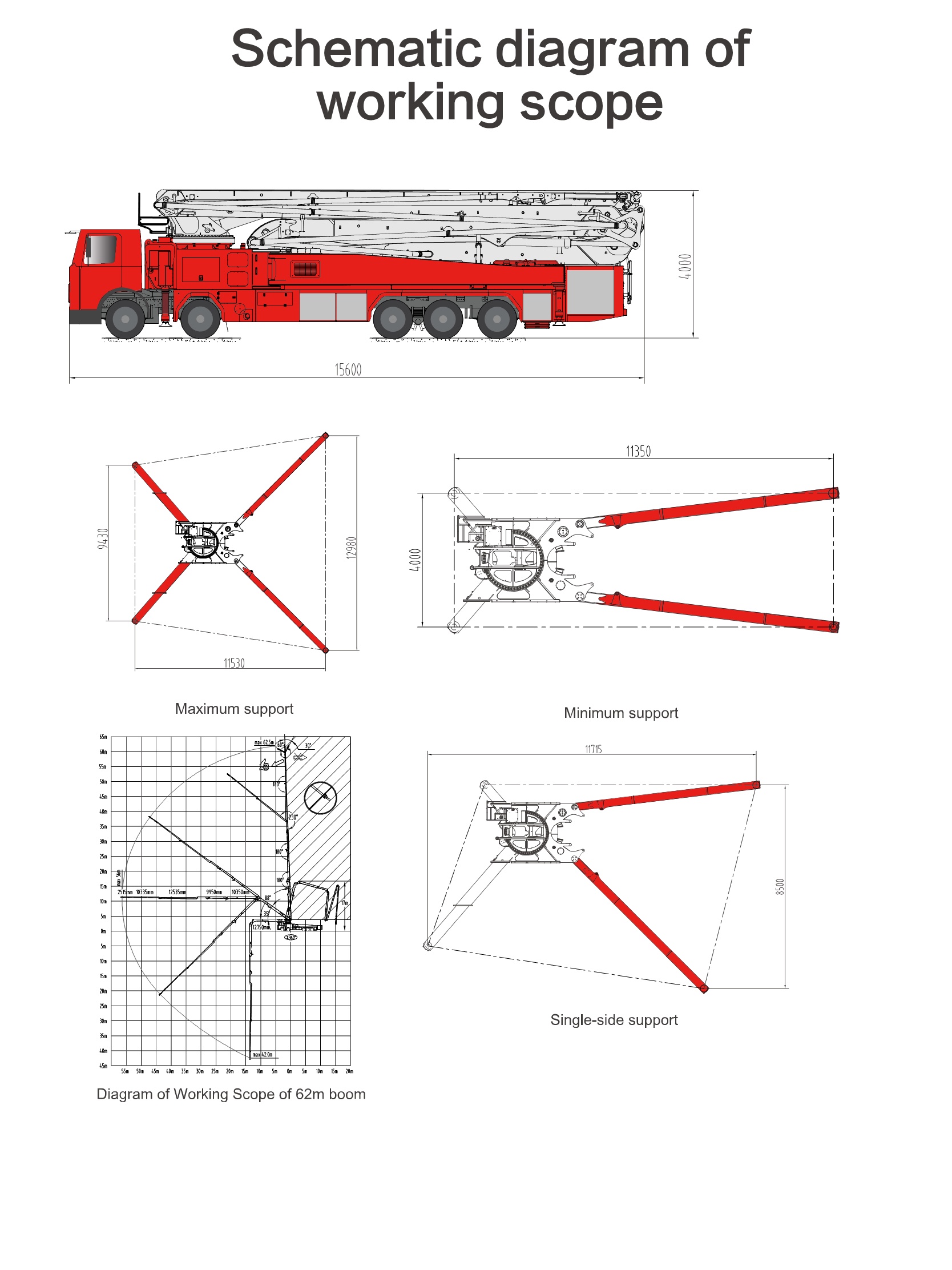

The vehicle structure design is the basis of the 38-meter high-lift jet fire truck, mainly including the chassis, lifting arm, turntable and cab. The chassis is made of high-strength steel to ensure the stability and carrying capacity of the vehicle under complex road conditions. The lifting arm adopts a multi-section telescopic design with a maximum lifting height of 38 meters. The arm frame is made of lightweight aluminum alloy material, which not only ensures strength but also reduces the weight of the vehicle. The turntable is designed as a 360-degree full-rotation structure to ensure that the fire truck can flexibly adjust the spray angle during operation.

2. Hydraulic system design

The hydraulic system is the core power system of the high-lift jet fire truck, which is mainly composed of hydraulic pumps, hydraulic cylinders, hydraulic motors and hydraulic pipelines. The hydraulic pump adopts a high-pressure and high-flow design to ensure the rapid extension and stable support of the lifting arm. The hydraulic cylinder adopts a double-acting design to achieve precise control of the lifting arm. The hydraulic pipeline adopts high-strength pressure-resistant materials to ensure the safety and reliability of the system under high-pressure environments.

ISUZU GIGA 38m Aerial Ladder Fire Truck with 14000L Water and Foam

| No. | Main Items | Technical Parameters |

| 2.1 | Model | PST5341JXFYT38 |

| 2.2 | Overall Dimension |

12000×2500×4000mm |

| 2.3 | Full Load Weight | 34000kgs |

| 2.4 | Number of the Crew | 1+1 (include driver) |

| 2.5 | Max. Speed | 90km/h |

| 2.6 | Capacity | 10000L Water & 4000L Foam. PP composite material liquid tank |

| 2.7 | Fire pump flow rate | 100L/s @ 10bar |

| 2.8 | Fire monitor | 5700L/min. flow rate, 70m shoot range |

| 2.9 | Max. working height | 32m |

3. Aluminum Superstructure

3.1 Cabin

3.2 Standardized Sub-frame

3.3 Compartment

3.4 Roller Shutter Door

3.5 Foot Pedals

4. Fire Fighting System

| No. | Main Items | Technical Parameters |

| 4.1 | Fire Pump | |

| 4.1.1 | Brand | POWERSTAR |

| 4.1.2 | Model | CB10/100 |

| 4.1.3 | Rated Flow Rate | 100L/s @ 10bar |

| 4.1.4 | Vacuum Pump | Electric vacuum pump |

| 4.1.5 | Priming Manner | Automatic |

| 4.1.6 | Suction Height | 7m |

| 4.1.7 | Priming Time | ≤80s |

| 4.1.8 | Location | Rear-mounted |

| 4.2 | Fire Monitor | |

| 4.2.1 | Brand | Optional |

| 4.2.2 | Model | Optional |

| 4.2.2 | Flow Rate | 950-5700L/min. |

| 4.2.3 | Shoot Range | Water ≥ 70 m, Foam ≥ 60 m |

| 4.2.4 | Location | On the top of the boom |

| 4.2.5 | Control Manner | Remote control |

| 4.2.6 | Horizontal Rotation Angle | 0°~355° |

| 4.2.7 | Pitch Rotation Angle | -45°~120° |

| 4.3 | Liquid Tank | |

| 4.3.1 | Capacity | Water 10000L, Foam 4000L |

| 4.3.2 | Material | PP composite material and Never Rust |

| 4.3.3 | Structure | Two Tank Manhole; One Overflow Device/Pressure Relief Device; Two Liquid Level Indicators; One Foam tank Drain Outlets with Valves; One Water tank Drain Outlets with Valves. |

| 4.4 | Control Panel | |

| 4.4.1 | Structure | Each fire extinguishing system is controlled by PLC, and different standardized control modules can be selected. IP56 protection level |

| 4.4.2 | Location | Rear pump room |

3. Electrical system design

The electrical system design includes control panels, sensors, cables and lighting equipment. The control panel adopts a touch screen design, which is easy to operate and can monitor the working status of the hydraulic system and the position of the lifting arm in real time. The sensor is installed at the key parts of the lifting arm to monitor the extension angle and load of the arm in real time to ensure safe operation. The cable adopts waterproof, oil-proof and high-temperature resistant materials to ensure normal operation in harsh environments. The lighting equipment adopts high-brightness LED lights to ensure the lighting needs of night operations.

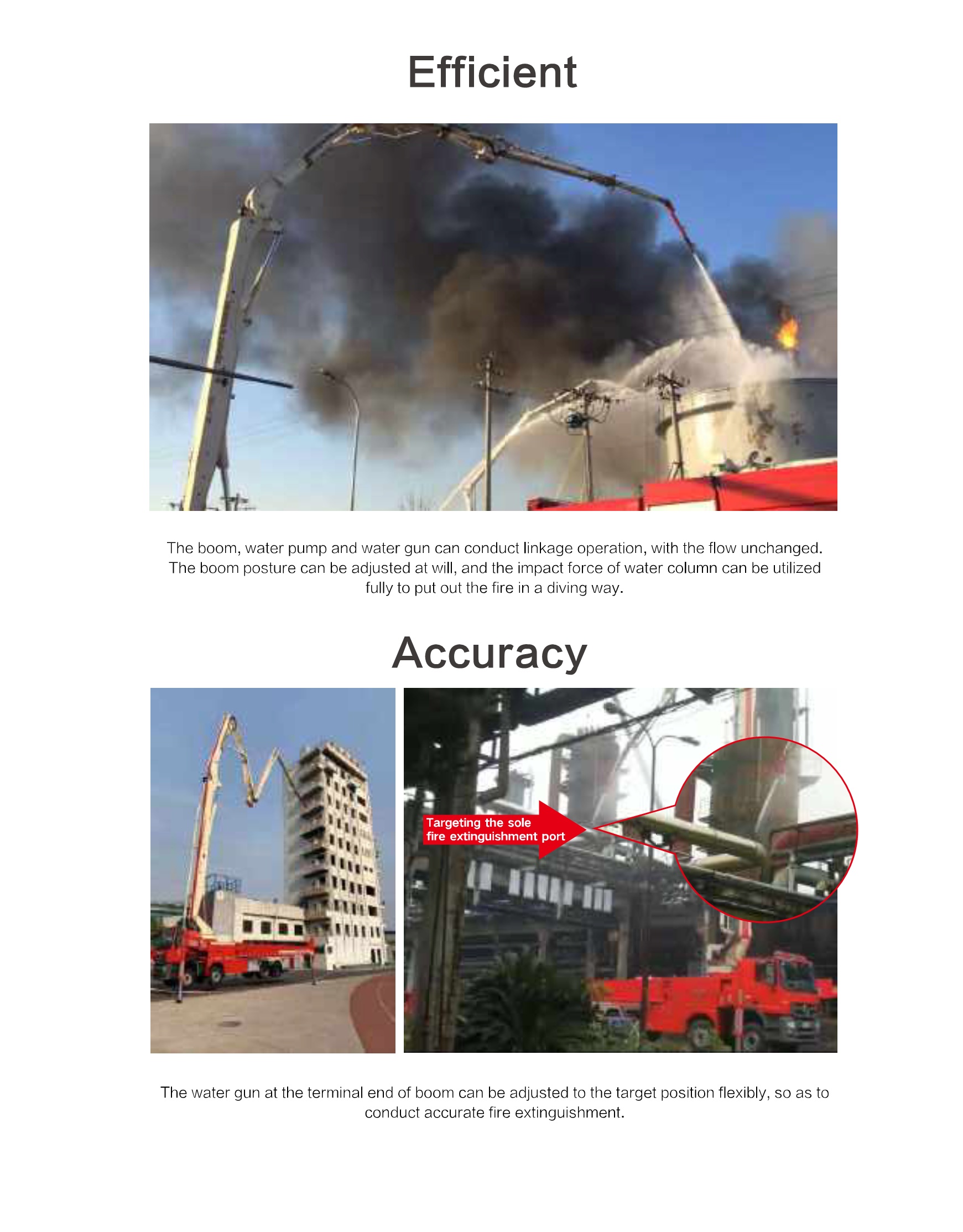

4. Spray system design

The spray system is the core functional part of the 38-meter high-lift jet fire truck, which is mainly composed of water pumps, water cannons, water pipes and water tanks. The water pump adopts high-pressure and high-flow design to ensure the spray distance and flow of the water cannon. The water cannon is installed at the end of the lifting arm, which can achieve 360-degree full rotation and up and down pitch to ensure the flexibility of the spray angle. The water pipe adopts high-strength pressure-resistant material to ensure safety and reliability in high-pressure environment. The water tank adopts a large-capacity design to ensure continuous water supply at the fire scene.

5. Safety design

Safety design is an important part of the 38-meter lifting spray fire truck, mainly including anti-rollover system, emergency stop system and overload protection system. The anti-rollover system monitors the tilt angle of the vehicle in real time through sensors. When the tilt angle exceeds the safe range, the system will automatically stop the extension and retraction of the lifting arm to ensure the safety of the vehicle. The emergency stop system is installed on the cab and control panel, which can quickly stop all operations in an emergency. The overload protection system monitors the load of the lifting arm in real time through sensors. When the load exceeds the safe range, the system will automatically stop the extension and retraction of the lifting arm to ensure the safety of the operation.

You may be interested in the following information