The most popular rescue fire truck in the fire department is of course the Emergency fire department Water fire truck Isuzu.

Water tank rescue fire truck Isuzu:

Function: In addition to the fire pump and equipment, the car is also equipped with a large-capacity water tank and water guns, water cannons, etc., which can transport water and firefighters to the fire scene to independently extinguish the fire, and is suitable for extinguishing general fires.

Popularity: Due to its simple structure, convenient operation and wide applicability, the Emergency fire department truck Isuzu is one of the most commonly used fire trucks in the fire department.

Foam fire truck Isuzu:

Function: It uses chemical fire extinguishing agents to extinguish special fires, especially suitable for extinguishing oil fires such as petroleum and its products, and can also extinguish flammable and flammable liquids, flammable gas fires, live equipment fires and general material fires.

Popularity: Isuzu foam fire trucks are very popular in places such as petrochemical enterprises that need to deal with special fire risks.

Side girder for water tanker fire truck

Features: made of welding high quality profiled steels, two longitudinal beams through a plurality of beam intensity bearing joint of high strength bolt connection. The side beam is installed, use girder structure, to ensure that the original car beam of uniform stress, improve the service life of the girder, and reduce deformation caused by components twisted.

● China best Fire department Rescue fire truck factory

● More than 500 workers, large and advanced production

● ISUZU Classic NPR series truck chassis

● Promptly delivery. any order is welcome

● 24 month quality guarantee term

ISUZU NPR 2 ton water tank fire truck

(Vehicle model: PST5110GXFSG20 / Isuzu water tank fire truck)

(Chassis model: ISUZU NPR)

Technical Specification

- Chassis parameters

Model: Isuzu NPR

Engine: ISUZU 4HK1

Power: 140 kW

Overall size (mm): length 6860 * width 2500 * height 2750

Drive type: rear-wheel drive

Wheelbase: 4,175 mm

Emission standard: GB3847-2005, GB17691-2018 country 6

2. pilothouse

Structure: flat head, original double row seat four door passenger room.

Seat setting: 2 people in front and 4 people in back.

Install a guardrail and handrail in front of the seat. On the way to the fire fighting and rescue, the firefighters quickly carried the air breathing apparatus. After arriving at the fire site, they quickly entered the fire fighting and rescue operations.

Cab structure: Install a suitable hydraulic tipping mechanism.

Equipment in the cab: except for the original vehicle equipment, install the force device control switch, 100W alarm, alarm light switch, etc.

Outside the cab: a long row alarm light is installed on the front of the top of the cab.

3. Water Tanker

Capacity: water: 2,000 Kg

Material: water tank: high-quality carbon steel plate, treated with high-tech anti-corrosion treatment

Structure: frame welding, vertical and horizontal anti-swing plate in the tank to reduce the impact of the water on the tank during the running of the vehicle, so that the tank has sufficient strength and stiffness.

The roof of the tank is equipped with a fast open manhole to facilitate the access of maintenance personnel. The tank is equipped with a device and a filter screen to prevent the pump from absorbing water and forming a vortex, thus affecting the flow rate.

The tank is provided with a stainless steel floating ball level indicator, which can display the capacity on the instrument panel; the bottom is provided with a discharge outlet with a ball valve.

The tank is equipped with a 76mm overflow pipe and two 76mm injection ports on each side of the compartment to facilitate water supply for other vehicles.

Equipment: 1 population hole, with quick locking and opening device.

1 liquid level indicator.

1 sewage outlet, with a stainless steel ball valve.

2 water injection ports (one for left and right)

Process: welding is firm and reliable, remove defects such as slag and deficiency welding; do 24-hour hydrostatic test after welding to ensure no leakage.

4. Fire pump and piping system

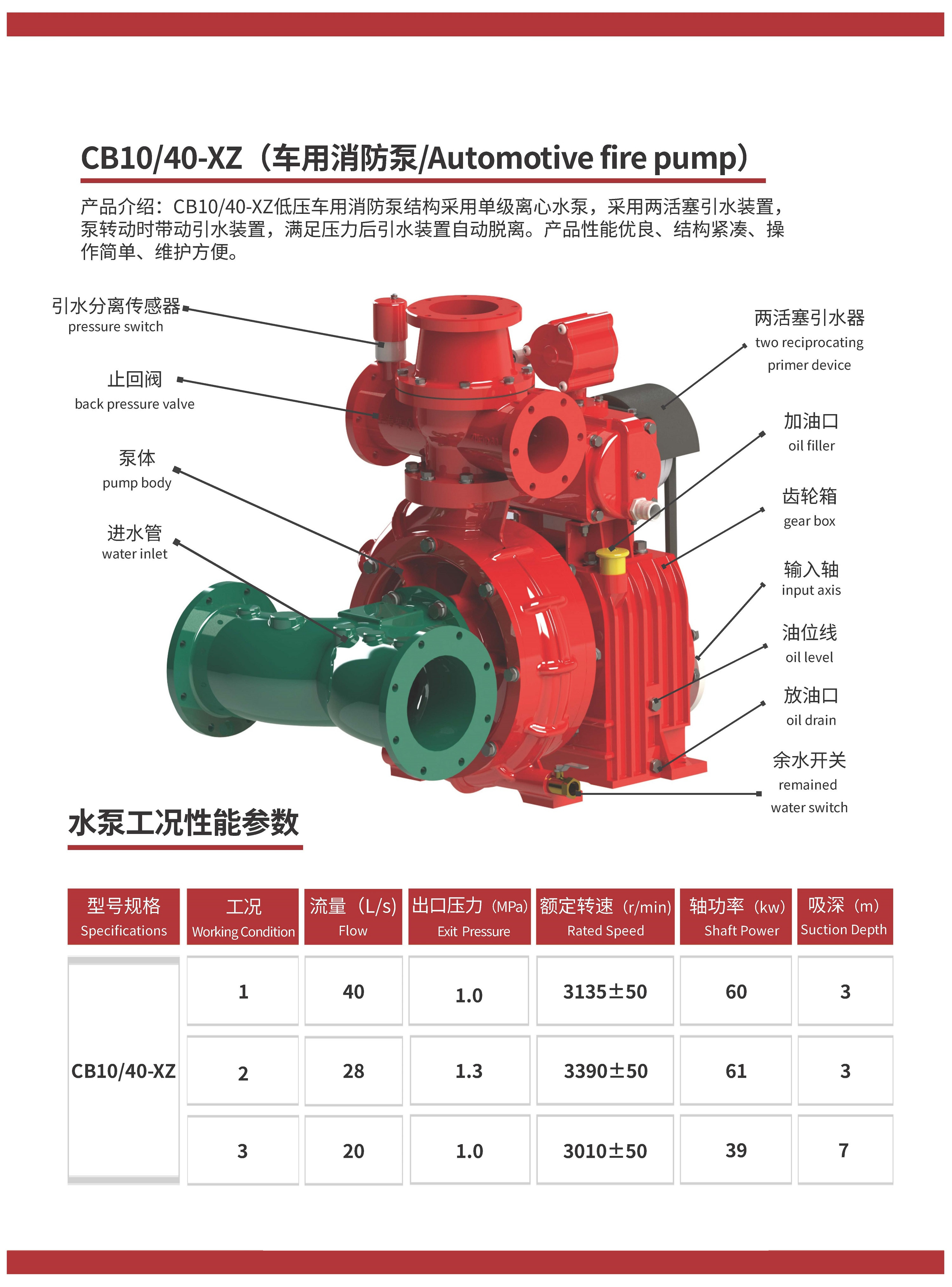

Fire pump: CB10 / 40 low-pressure fire pump (Shanghai shen)

Flow rate: 40L / s

Pressure: 1.0MPa

Installation type: rear position

Vacuum pump: piston type;

Vacuum pump material: wear resistance, corrosion resistance to meet the sealing requirements;

Water diversion time is 35s, and the suction depth is 7m.

Maximum vacuum degree: 85 kPa;

pipe system

pipe system

Water suction line: the pump is equipped with Φ150mm water inlet, can absorb water from natural water source, liquid tank, fire reservoir, and can be added to connect the fire hydrant water supply, water suction pipe placed on the roof.1 water inlet with Φ150mm butterfly valve for connection to the water tank.

Water outlet road:

The roof is equipped with a Φ100mm water outlet fire gun pipeline and control valve, using a flexible joint;

One Φ 80mm and one Φ 65mm manual ball valve controlled outlet are provided on the left and right sides of the pump room.

Water injection pipeline: 1 Φ 65mm pump water injection pipeline and control valve in the tank;

There are two Φ 65mm water injection pipes on the left and right sides of the car, which can be injected into the tank, with the inner buckle interface and the stuffy cover.

Waste water pipe: in order to protect the water pump and each ball valve, the waste water pipe is installed in the pipeline, and respectively equipped with ball valves.

Cooling water pipeline: in order to make the force collector cope with various complex situations, it is equipped with a cooling water pipeline and control valve connected with the inlet and outlet water pipe.

5. fire monitor

Model: PS30 fire gun (West)

Flow rate: 30 (L / s)

Range: 60m of water

Pressure: 1.0MPa

Location: Located on the top of the water tank.

Control: adopt manual control with locking mechanism for easy operation.

6, force collector

Type: full-power sandwich force collector

Cooling mode: forced water cooling type

Lubrication mode: splash-type oil lubrication

Operation mode: the force collector is operated at the instrument panel in the cab, which is convenient and smooth.

Installation: the force collector is well matched with the engine, accurately installed, and there is no falling off after combination.

7. Equipment box and pump room

Main material:

The skeleton and skin are made of high strength carbon steel; the internal rack is made of aluminum alloy profile and the interior panel is oxidized aluminum plate.

fundamental structure:

1, for the overall structure, the front for the equipment box, the middle for the water tank, the back for the pump room.

2. The rear is pump room, equipped with instrument panel and operating system, equipment box and pump room are equipped with locked curtain door. Frame solds the structure and ensures its strength and stiffness.

3, the space can be adjusted at will, and the equipment box is equipped with drainage holes.

4, the equipment box is reliable, beautiful, can be adjusted at will, equipped with a large space curtain door equipment box, to ensure the full use of the space.

5. The carriage and pump room are equipped with lights to meet the lighting needs of fire fighting at night.

Aluminum alloy rolling shutter door:

1, all equipment box and pump room are used with lock shutter door, handle and lock pin durable, no deformation, sealing performance after water shower experiment, to ensure no leakage phenomenon.

2. There are rivets in the slide on both sides of the shutter door so as to avoid falling off.

3. There are lights in each equipment box, which are controlled by the opening and closing of the rolling shutter door.

4, the rear left, right each an aluminum alloy curtain door, a rear tail, safe and reliable, beautiful and practical.

fundamental principle:

(1) Integration of design equipment according to combat composition and combat operation;

(2) Design various equipment brackets according to the ergonomic principle;

(3) No need for any climbing tools, take any of the equipment in the box.

(4) Place the equipment according to the logical relationship and frequency of use;

(5) Stand on the ground or on the pedal in the 1-2 action to take any equipment.

Eight, electrical system

1. The top of the cab is equipped with a red long row of luxury alarm lights.

2. The power of the alarm is 100W;

3. In order to ensure the safety of the use, the whole vehicle line is made of the overall wiring harness, and the waterproof plug is used at the connection point to ensure the safety of the line in the process of use.

4. The roof is equipped with 1 fire lighting lamp; safety sign lights under the two sides of the vehicle, and the body and tail paste reflective signs according to the standard.

5. All equipment boxes are installed with LED lights to facilitate night combat lighting.

6. On both sides of the vehicle are equipped with three flashing lights and side lights (combination), safety sign lights and side reflector (combination), equipped with front and rear profile lights, one turn signal on each side, and lights in the passenger room, equipment box and pump room.

7, alarms, alarm lights, strobe lights, circuits are independent additional circuits, control devices are installed in the cab.

8. All lines are protected by casing, and different colors are used to distinguish the connection form and function.

9. Equipment on the instrument panel in the pump room: liquid level gauge, tachometer, pressure gauge, vacuum gauge, equipment box lighting switch, etc.

IX. Instrument panel and on-board equipment

1. The instrument panel is located in the pump room at the rear end of the car, with a control board and sufficient lighting;

2, all control handles, switches, indicator lights near the Chinese logo;

3, there are operation steps description.

4. All signs are persistent and high attachment, and can withstand the effects of temperature and climate.

5, the operation panel uses high quality aluminum plate, beautiful, durable, the overall weight is light.

6. The operating system of the pump room is set at the rear of the vehicle, without pressure outlet, to ensure the safety of the operator, and there are panel lights.

Ten, with the car documents

1) Chassis use instruction manual 2) Chassis quality warranty card

: 3) Chassis maintenance manual: 4) Chassis qualification certificate

5) List of vehicle tools 6) Engine number rubbings

7) Chassis number rubbing; 8) Fire engine operation manual

9) List of fire engine fire fighting equipment 10) Fire engine certificate

11) Fire truck tracking service card 12) Fire protection exchange list

Equipment equipped with table

| order number |

name |

unit |

quantity |

remarks |

| 1 |

fire hose |

tray |

10 |

Type 13 Φ65 mm6 disk

Type 13 Φ80 mm4 disk |

| 2 |

Water injection water belt |

rice |

1 |

Type 1365 inner buckle |

| 3 |

DC water gun |

branch |

1 |

|

| 4 |

Flower water gun |

branch |

1 |

|

| 5 |

dry-chemical fire extinguisher |

With |

1 |

3 kg, ABC dry powder |

| 6 |

Water collector |

piece |

1 |

|

| 7 |

Divisional water |

piece |

1 |

|

| 8 |

Water suction tube wrench |

individual |

2 |

|

| 9 |

rubber hammer |

individual |

1 |

|

| 10 |

Ground fire hydrant wrench |

piece |

1 |

|

| 11 |

Underground fire hydrant wrench |

piece |

1 |

|

| 12 |

The belt bridge |

individual |

2 |

|

| 13 |

Water belt wrapped cloth |

piece |

4 |

|

| 14 |

Water belt hook |

piece |

4 |

|

| 15 |

a firemans axe |

piece |

1 |

|

| 16 |

Fire suction pipe |

rice |

8 |

|

| 17 |

Water suction pipe filter |

single |

1 |

One suction pipe per 8 m |

| 18 |

Different diameter interface |

single |

2 |

Bubuckle Φ 65 variable Φ 80 |

The process of fire brigade purchasing Emergency fire department truck Isuzu usually includes the following key steps:

1. Demand analysis and model selection

Demand analysis: The fire brigade first needs to clarify its own needs, including the purpose, performance requirements, load capacity, ease of operation, etc. of the Emergency fire department truck Isuzu, as well as the budget range.

Model selection: According to the results of the demand analysis, the fire brigade can contact the regular fire truck manufacturer with production qualifications to learn more about the performance, price, after-sales service and other information of different models, so as to choose the model that best suits its needs.

2. Contract signing and vehicle production

Contract signing: After selecting the model, the fire brigade needs to sign a legal and compliant Emergency fire department truck Isuzu purchase contract with the manufacturer to clarify the vehicle configuration, price, delivery time, after-sales service and other terms.

Vehicle production: The manufacturer starts to produce the Emergency fire department truck Isuzu according to the contract requirements. If the fire brigade needs to customize special configurations or functions, it should be clarified with the manufacturer when the contract is signed and supervised during the production process.

3. Vehicle acceptance and delivery

Vehicle acceptance: After the vehicle is produced, the fire brigade needs to conduct acceptance together with the manufacturer. The acceptance content includes whether the vehicle's appearance, performance, configuration, etc. meet the contract requirements, and whether the accompanying documents are complete (such as chassis certificate, vehicle certificate, one-time certificate, environmental protection list, purchase tax declaration form, vehicle invoice, etc.).

Delivery and use: After the acceptance is qualified, the fire brigade pays the balance, and the manufacturer delivers the Emergency fire department truck Isuzu to the fire brigade for use.

4. Vehicle licensing and insurance processing

Vehicle licensing: After the fire truck is purchased, it is necessary to go through the licensing procedures in accordance with the licensing standards of the local vehicle management office. This includes preparing relevant documents (such as motor vehicle sales unified invoice, vehicle certificate, etc.), filling out application forms, and conducting vehicle inspections.

Insurance processing: According to the relevant national policies, new cars must first apply for motor vehicle insurance before going through the household registration procedures. The fire brigade needs to purchase corresponding insurance for the fire truck to ensure that the vehicle can be compensated in time in the event of an accident.

5. After-sales service and training

After-sales service: The manufacturer should provide comprehensive after-sales service, including vehicle warranty, maintenance, and spare parts supply. If the fire brigade encounters problems during use, it should contact the manufacturer in time to solve them.

Operation training: In order to improve the operation skills and emergency handling capabilities of firefighters, the manufacturer or fire brigade can organize professional personnel for operation training. The training content includes vehicle operation, maintenance, troubleshooting, etc.

pipe system

pipe system