The Isuzu ELF 160HP light-duty fire truck is built on the sturdy ISUZU KV600 light-duty chassis. The Isuzu mini truck can challenge all kinds of bad roads. It is equipped with a 3000-liter large-capacity tank and a professional fire pump. This Isuzu mini 160HP fire water truck provides a solid guarantee for fire safety and demonstrates excellent performance and flexibility.

The Isuzu KV600 mini fire fighting truck's double-row cab provides enough space and quality to load firefighting equipment and maintain good driving performance. The cab can accommodate 5 firefighters and is equipped with heating and cooling air conditioning

Truck Model:

PST50704SXFTanker Structure:

High quality stainless steelWork capacity :

2000L Water + 1000L FoamWheelbase:

3360mmAxle drive:

4x2Engine Power:

160HPEngine Model:

4KK1Fire Pump:

CB10/30, 1600L/minFire Monitor:

PL32-64YRemark:

Stainless steel tank body, light-dutyThe Isuzu ELF 160HP light-duty fire truck is built on the sturdy ISUZU KV600 light-duty chassis. It combines excellent power and environmentally friendly emissions. The Isuzu mini truck can challenge all kinds of bad roads. It is equipped with a 3000-liter large-capacity tank and a professional fire pump. It has a long spray distance and a control panel language that can be selected. At the same time, it provides a variety of optional configurations to meet different needs. This Isuzu mini 160HP fire water truck provides a solid guarantee for fire safety and demonstrates excellent performance and flexibility. The Isuzu KV600 mini fire fighting truck's double-row cab provides enough space and quality to load firefighting equipment and maintain good driving performance. The cab can accommodate 5 firefighters and is equipped with heating and cooling air conditioning to ensure that the driver can stay comfortable in any weather conditions. In addition, the design of the cab also takes into account the convenience and safety of driving.

● China best fire fighting truck factory

● More than 500 workers, large and advanced production

● Be designed according to your requirements

● Promptly delivery. any order is welcome

● 24 month quality guarantee term

Specification:

|

Product Name |

ISUZU KV600 160Ps mini fire fighting truck |

||

|

Chassis Series |

ISUZU KV Series |

||

|

Vehicle Model |

PST50703MXF |

||

|

Main specifications |

Manufactory |

Powerstar |

|

|

Overall dimension(L*W*H) |

6300×2250×2860mm |

||

|

GVW |

7300Kg |

||

|

Curb weight |

4300Kg |

||

|

Water tank volume |

3,000 liters |

||

|

Cabin |

double cabin, 2+3seats,with Air conditioner, electronic windows, USB |

||

|

Suspension F/R |

mm |

1335/2230 |

|

|

Wheel base |

3815 |

||

|

Driving type |

4*2 |

||

|

Chiassis model |

ISUZU ELF |

||

|

Number of axles |

2 |

||

|

Tire specification |

7.00R16 with one spare tire |

||

|

Number of Tires |

6+1 |

||

|

Passengers in cab |

3+3 |

||

|

Engine |

Engine model |

4KK1 |

|

|

Type of fuel |

Diesel |

||

|

Displacement/power |

2.5L / 160 Ps |

||

|

Max speed |

95 Km/h |

||

|

Emission standard(TAS) |

EURO 6 |

||

|

Fire performance |

Tank capacity |

water tank capacity:2000kg |

|

|

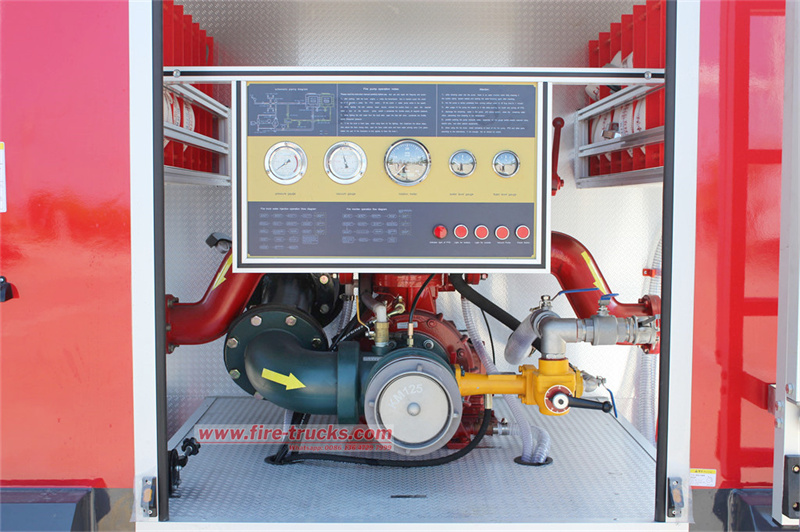

Fire pump |

China Top brand |

||

|

Model: CB10/30 |

|||

|

Low-pressure:30L/S |

|||

|

Medium-pressure:60L/S |

|||

|

Fire monitor |

China Top brand |

||

|

Model:PL32-64YZ |

|||

|

Flow:32L/S |

|||

|

Water jet distance:≥45m |

|||

|

Fire pump Input |

1 unit, diameter: 100mm |

||

|

Fire pump Outlet |

2 units, diameter: 65mm |

||

|

Standard configurations |

Water pump operation panel in English, fender should be black, with alarm light, detachable ladder, body rear equipment box under the direction of the upward tilt of about 45 degrees, all interfaces of the vehicle and accessories are British, with a 30m roll of black high-pressure hose |

||

What standards are required to make high-quality ISUZU KV600 fire truck?

1. Strengthening process of Isuzu mini chassis

♦ High-precision welding and reinforcement: Robot welding technology is used to reinforce the key load-bearing parts of the ISUZU KV600 160HP drive chassis (such as beams and suspension brackets) in multiple layers to ensure torsional strength and durability under rugged road conditions.

♦ Precision assembly of four-wheel drive system: core components such as transfer cases, differential locks, and drive shafts must pass dynamic balance tests and match full-time four-wheel drive logic to ensure traction distribution on complex roads.

♦ Anti-corrosion treatment: The chassis is electrophoresis coated + multi-layer anti-rust sprayed, and passes the salt spray test to cope with the corrosive environment where fire trucks are frequently exposed to water and chemical agents.

2.Integration of special upper structure and functional components

♦ Manufacturing of large-capacity water tanks:

Material selection: Use high-quality stainless steel or high-strength composite materials, with antibacterial coating on the inner wall and anti-collision frame on the outer wall.

Dynamic stability design: The center of gravity distribution under full load should be simulated during installation, and the hydraulic damping bracket should be combined to reduce the impact of water sway during driving on the control of the ISUZU KV600 fire fighting truck.

♦ Fire pump system matching:

High-pressure pipeline integration: Use aviation-grade aluminum alloy pipelines, laser welding of interfaces to ensure sealing, and the pump pressure must pass the ISO 9001 certified test bench for 72 hours of continuous full-load testing.

Intelligent control integration: The control panel must support multi-language real-time switching, and the electrical circuit adopts a redundant design and has an IP67 waterproof rating.

3. Flexible manufacturing system for customized production

♦ Modular production line design:

Adopt AGV logistics + digital assembly system, support rapid switching of water tank capacity (3000L), pump type (medium pressure/high pressure), cloud control platform and other configurations.

♦ Full life cycle test:

Each Isuzu off-road fire truck needs to complete a 3,000-kilometer comprehensive road test (including 40% off-road sections), simulated fire scene high-temperature spray test.

4. Intelligent and data traceability management

♦ Digital process control:

Key components (such as pumps, valves, and sensors) are implanted with RFID chips to achieve full-cycle data traceability from production to service to maintenance. The AR-assisted assembly system is used to ensure zero-error installation of complex pipelines.

♦ Remote operation and maintenance support:

Pre-installed Internet of Vehicles terminals monitor vehicle status in real time and provide fault warnings, and support OTA upgrades of fire pump control algorithms.