new or used Isuzu Fire Rescue Truck mounted Crane is a specialized firefighting and rescue vehicle equipped with an integrated crane system, designed to handle heavy lifting and complex rescue operations during emergencies. The crane (typically ranging from 3 to 15 tons in capacity) enables lifting and moving debris, vehicles, or equipment at disaster sites.

Truck Model:

PST5180GXFHTanker Structure:

Fire equipmentsWork capacity :

5Tons boom craneWheelbase:

4500mmAxle drive:

4x2, LHDEngine Power:

240HPEngine Model:

ISUZU 6HK1-TCFire Pump:

WithoutFire Monitor:

PL40Remark:

4x4 drive avaiableHeavy rescue fire trucks Isuzu, (also named as Isuzu Emergency fire trucks with cranes or Isuzu brand Rescue Vehicle with crane) are special vehicles that integrate emergency rescue and engineering machinery functions. Its core equipment includes retractable crane arms, winch systems, lighting equipment and demolition tools, and is equipped with special firefighting equipment such as high-pressure water guns and smoke exhaust devices. This type of vehicle can quickly lift, tow, and demolish obstacles, and simultaneously perform tasks such as fire extinguishing and smoke exhaust, which is suitable for multi-task collaborative operations in complex disaster scenarios.

● China best Water fire truck factory

● More than 500 workers, large and advanced production

● Be designed according to your requirements

● Promptly delivery. any order is welcome

● 24 month quality guarantee term

1. Scope of application

This type of fire truck is widely used in the following scenarios due to its versatility:

Traffic accident rescue: The crane arm can quickly clean up vehicle wreckage or lift heavy objects to rescue trapped people; the winch is used to tow overturned vehicles.

Building collapse search and rescue: Use the lifting function to move large building materials and cooperate with demolition tools to open up life channels.

Natural disaster disposal: In disasters such as earthquakes and mudslides, clear road obstacles and assist in the construction of temporary facilities.

Industrial Accident Emergency: When dealing with accidents such as hazardous chemical leakage and equipment collapse, precise operation can avoid secondary injuries.

Water rescue assistance: The boom can assist in salvaging vehicles that fall into the water or fixing rescue boats.

2. Specifications of truck cranes

The lifting capacity of truck cranes varies greatly according to the design of the vehicle model. The rated load range of mainstream models on the market is currently 3 tons to 20 tons. Some heavy-duty rescue vehicles can carry larger tonnage booms (such as 30 tons), but they need to be selected in combination with the vehicle body's load-bearing capacity and mission requirements. In actual applications, the boom's telescopic height, rotation angle and control flexibility are also key indicators.

3. International application status

In developed countries such as Europe, the United States, Japan and South Korea, fire trucks with truck cranes have become standard configurations of urban comprehensive rescue systems. For example, German fire departments are generally equipped with such vehicles to deal with high-rise building rescue and industrial accidents; the United States focuses on its rapid response capabilities in earthquake-prone areas. The penetration rate in developing countries is low due to budget constraints, but demand has been on the rise in recent years.

4. Procurement channel recommendations

Official authorized manufacturers: Well-known fire equipment companies at home and abroad (such as Magirus in Germany and XCMG in China) provide customized models, which can be connected through official websites or agents.

International fire exhibitions: Such as the China International Fire Exhibition and the Hannover Fire Exhibition in Germany, where you can directly contact the latest technology and negotiate purchases.

Government bidding platform: Government procurement websites of various countries regularly release fire truck procurement projects, which are suitable for bulk purchases or units with limited budgets.

Second-hand equipment market: Retired vehicles in European and American countries are cost-effective after refurbishment, but they need to be strictly tested for compliance and performance status.

|

|

Model No

|

QL5190GXFDMFRY

|

Engine

|

Model NO

|

6HK1-TCSG40 240hp

|

|

|

Gross weight

|

16800kg

|

Rated Torque

|

1560N·m/1200-1500(r/min)

|

|||

|

Fire Pump

|

Model No

|

LXB15/40-125-80

|

Piston vacuum pump

|

vacuum≥85kPa,

height≥7m

|

||

|

Power

|

60Rated:40L/S 1.5MPa

|

|||||

|

Fire monitor

|

Model No

|

PL40

|

Angle

|

Horizontal

|

0-360°

|

|

|

Range

|

80M(foam)/95M(water)

|

Pitch angle

|

-30°-70°

|

|||

|

Rated flow

|

40L/S 1.3MPa

|

|||||

|

Lift lighting system

|

Model No

|

YZH4-5.04CA

|

Engine

|

Model No

|

SH6500EXS

|

|

|

Main lamp power

|

4×1000W

|

Rated voltage

|

220V

|

|||

|

Height

|

≥7.0m

|

Rated power

|

5kW

|

|||

|

Charging device

|

Model No

|

YYKJ-CD-24V

|

Output voltage

|

24V

|

||

|

Input voltage

|

220V

|

Outlet Power

|

0.8MPa

|

|||

|

Foam mixer

|

Model No

|

PH64

|

||||

|

Mixture ratio

|

3%-6%

|

|||||

|

Traction winch

|

Model No

|

USA champion N12000XF

|

Pulling

|

5443kgf

|

||

|

voltage

|

24VDC

|

Gear ratio

|

402:1

|

|||

|

Power

|

4.8kW

|

Working speed

|

5.6m/min

|

|||

|

Water tank

|

5000L (Optional)

|

Foam tank

|

2000L (Optional)

|

|||

Guide to selecting truck crane types

1. Comparison of core types

Straight-arm truck crane

Features: simple structure, boom can be extended and retracted by wire rope, large working radius (up to 20 meters), suitable for vertical lifting and open environment operation.

Applicable scenarios: construction sites, large equipment handling, heavy material lifting.

Disadvantages: The boom needs to be placed horizontally during transportation, which occupies a large space and has low efficiency for complex movements.

Folding-arm truck crane

Features: driven by multiple hydraulic cylinders, the boom can be folded and retracted, the movement is flexible and efficient, and it supports the installation of auxiliary tools such as working platforms.

Applicable scenarios: warehouses, factories, narrow space rescue and multi-functional operations (such as high-altitude maintenance).

Disadvantages: small working radius, high operation complexity, and the price is usually higher than the straight-arm type.

U-arm truck crane (special type)

Features: lightweight design, U-shaped boom cross-section, taking into account both strength and flexibility.

Applicable scenarios: Small and medium-sized lifting tasks that require frequent movement, such as logistics loading and unloading.

2. Tonnage selection recommendations

Light tasks (2-5 tons): Suitable for urban logistics and small construction site handling, emphasizing mobility and low cost.

Medium tasks (6.3-8 tons): Suitable for building materials transportation, port loading and unloading, balancing carrying capacity and flexibility.

Heavy tasks (12 tons and above): Need to be matched with a high-load-bearing chassis (such as front four and rear eight models) for bridge construction and large equipment installation.

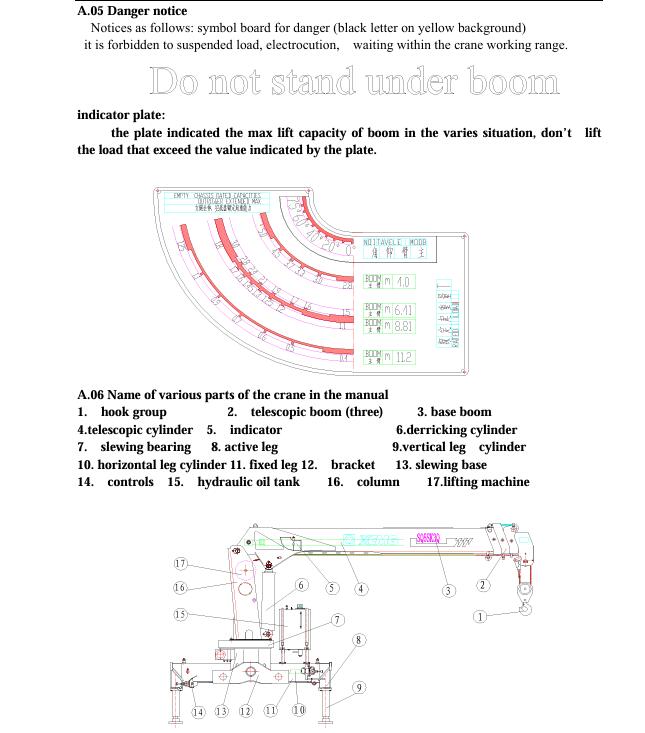

| Truck mounted crane structure parameters | ||||

| Van dimensions | 5550X2294X600mm | Maximum loading of crane | 5 tons | |

| XCMG crane | ||||

| Crane model | SQZ105 | Maximum lifting height | 11m | |

| Maximum working radius | 8m | Maximum loading | 5 tons | |

| Crane type | Knuckle boom | Telescopic arms number | 3 | |

| Hydraulic, turning angle 360° | Color and Logo | Optional | ||

| Standard configuration | Chassis,sub frame,van body,XCMG Knuckle boom truck crane equipped between the cabin and van body,mechanical leg. | |||

| Selective configuration | 2-20 tons XCMG straight arm truck crane,1-30 tons XCMG Knuckle boom truck crane,other brand truck crane,crane equipped at the rear of van body,lifting hydraulic cylinder for unloading,hydraulic legs,aerial working seat. | |||

3. Chassis and configuration selection

Chassis type

Light tasks can choose a single-bridge chassis (such as Dongfeng, JAC), and heavy tasks require a rear eight-wheel or front four and rear eight chassis (such as Shaanxi Automobile, Jiefang).

It is recommended to choose a four-wheel drive chassis in mountainous areas or complex road conditions.

Key configuration

Cargo compartment: Prioritize the through-subbeam design, and the material thickness ≥5mm to improve the anti-deformation ability.

Outrigger: The stability of the double-chamber outrigger is better than that of the single-chamber one, and it is suitable for soft foundation or large-tonnage operations.

4. Comprehensive decision-making suggestions

Prioritize matching scene requirements:

Select the straight arm type (cost-effective) for open construction sites; select the folding arm type (flexible and efficient) for narrow environments.

For frequent short-distance transportation, the U-shaped arm (lightweight) is recommended.

Budget and maintenance cost: The straight arm type has low purchase cost but single function; the folding arm type has high initial investment but strong scalability.

Operation convenience: The straight arm type is recommended for novices (simple operation); the folding arm type can be selected for skilled teams to improve efficiency.