There are many manufacturers of emergency fire rescue trucks. Among them, the Isuzu giga fire rescue truck produced by POWERSTAR TRUCKS has high stability, good safety, and good intelligence. The car body is made of high-quality steel, equipped with water tanks and foam tanks inside, and equipped with a variety of fire-fighting equipment and tools. The suspension and brake systems are advanced, and the information system can monitor the vehicle status in real time to ensure the smooth execution of firefighting tasks. This emergency special vehicle from POWERSTAR TRUCKS has an excellent equipment box material, a stable structure, good sealing, and is equipped with a variety of practical systems.

Truck Model:

PST5250GXFTanker Structure:

4000L waterWork capacity :

5 ton craneWheelbase:

4500mmAxle drive:

4x2Engine Power:

240 HpEngine Model:

ISUZU 6HK1Fire Pump:

CB10/60Remark:

Special fire equipments availableISUZU GIGA fire rescue truck is a modular special vehicle that combines heavy-duty performance with intelligent rescue technology. Its core design concept is "all-weather and all-terrain response". This model is equipped with a 6UZ1-TCG51 engine with a maximum output of 350 horsepower and a 12-speed manual transmission. It can start in extreme cold at -40℃ and can be called a mobile emergency command center. Its nickname reflects its functional diversity: it is called "GIGA fire rescue truck" in the East Asian market, and Nordic users call it "speed rescue platform". In the industrial field, it has become the gold standard for special vehicle modification with the name of "modular integrated chassis system".

I,Main characteristics

● China best Emergency rescue fire truck factory

● More than 500 workers, large and advanced production

● Be designed according to your requirements

● Promptly delivery. any order is welcome

● 24 month quality guarantee term

III,Basic Description

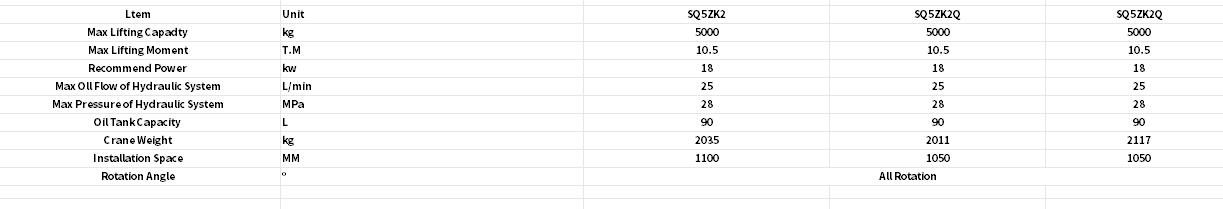

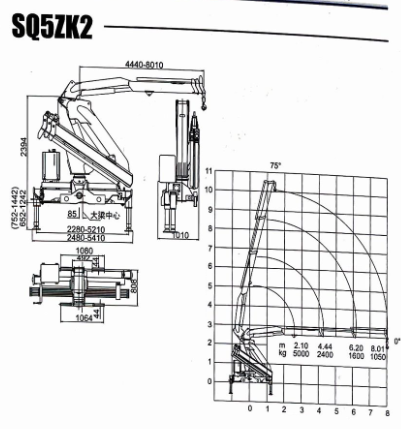

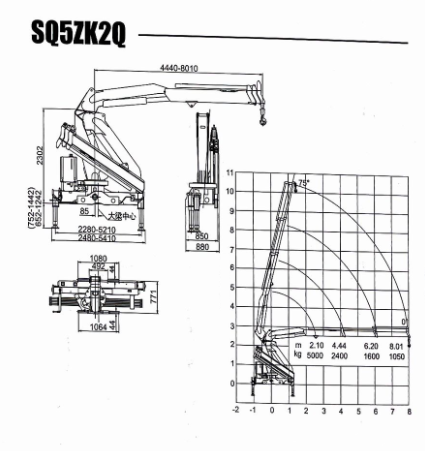

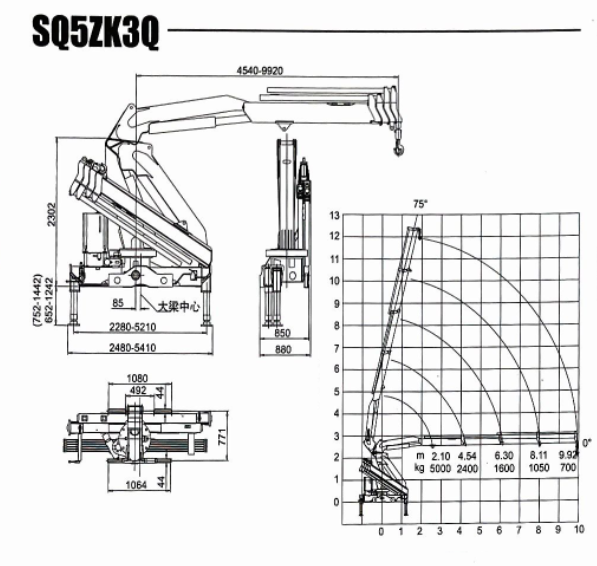

JY80 emergency rescue fire truck is equipped with the original U.S. champion electric winch N16800XF; it adopts Honda generator SHT11500; the roof is equipped with lifting lighting system YZH4-5.04CA; and the rear is equipped with a hydraulic truck crane SQ5ZK2 produced by XCMG. The equipment compartment adopts the structure of rotation and pulling, which has a high integration degree, and is convenient to use.

This vehicle has a novel appearance, reasonable layout, and convenient operation, which makes it more close to the needs of the actual rescue, and it is a necessary and ideal rescue fire fighting vehicle for public security fire forces and petrochemical, oil transportation terminal, airport and other full-time fire brigades.

Genetic map of the builders

To become an ISUZU GIGA officially certified builder, the company needs to break through three technical barriers:

Cold zone engineering accumulation: master polar technologies such as low-temperature alloy welding and antifreeze hydraulic systems to ensure that the vehicle maintains more than 95% operating efficiency in ice and snow environments

Intelligent integrated innovation capabilities: independently develop on-board AI dispatching systems to achieve multi-system linkage such as water tanks, foam spraying, and ladder control

Global certification matrix: meet the Chinese GB7956 and EU EN1846 fire truck standards at the same time, and pass the explosion-proof ATEX certification

Powerstar Trucks' blazing territory

As a strategic partner of ISUZU GIGA, Powerstar Trucks has built a three-dimensional firefighting equipment ecosystem:

① Special chassis platform: launch the world's first hydrogen fuel cell fire truck chassis, with a range of over 800 kilometers, equipped with active balancing suspension, and adaptable to complex terrains such as mountains and swamps. ② Multifunctional derivative series: including 20-ton high-flow remote water supply system, foldable high-rise rescue channel vehicle, and fire robot mother vehicle with demolition function. ③ Intelligent Command Center: Develop a 5G-connected disaster simulation system to generate 3D fire scene heat maps in real time. The command vehicle is equipped with a satellite communication array, which can maintain 72 hours of emergency communication in a network-off environment.

In the wave of the fire technology revolution, these steel behemoths are redefining the time and space boundaries of disaster rescue with disruptive innovations - when fire and ice and snow intertwine, the belief in technology will eventually be melted into the ultimate armor to protect life.

parameters of the fire fighting water tank truck

| ISUZU Euro IV 4x2 190hp 12000 liters water tanker fire fighting truck parameters | ||||||

| Chassis | ||||||

| Cabin | Brand: ISUZU | |||||

| FTR, 4x2 left hand drive, | ||||||

| with air conditioner, 2 seats, with USB,radio, loud speaker | ||||||

Vehicle Main Dimensions |

Overall dimensions (L x W x H) mm: 9200*2330*2780 mm | |||||

| Wheel base: 5000 (mm) | ||||||

| Overhang (front/rear): 1335/2665(mm) | ||||||

| Approach angle: 26° | ||||||

| Departure angle: 16° | ||||||

| Weight in KGS | Curb Weight:7805 kg | |||||

| Payload: 12tons | ||||||

| Max. driving speed(km/h) | 90 | |||||

Engine |

Brand | ISUZU | ||||

| Model | 6HK1-TCG61, EURO IV | |||||

| Emission | 11 l | |||||

| Horse power | 380HP | |||||

| PowerType | 4-stroke direct injection , 4-cylinder in-line with water cooling, turbo-charging and inter-cooling | |||||

| Gearbox | 8 Forwards gear & 1 reverse gear | |||||

| Tire | 295/80R22.5, 6 pcs+1 spare tire | |||||

| Axle | Front axles 6.3, rear axle 13t | |||||

| Brake | Air brake | |||||

| Upper parameters | ||||||

| Water tank volume | 4000 liters | |||||

| Manhole in the tank | DN450 | |||||

| Thickness | 5mm | |||||

| Material | Carbon steel and high tensile steel | |||||

| Standard configuration of the tank | Equipped with front, side and Sprinkler (Sprinkling width>14m) Equipped with fire fighting pump pump (Suction lift >6m) Equipped with fire valve, water valve, and filter gauze. Equipped with water cannon. rubber padding between tanker and chassis Equipped with water pump Equipped with fire brigade system, fire gun on top, (Sprinkling width>60m) |

|||||

| fire fighting pump | ||||||

| Type of pump | Centrifugal pump | |||||

| Minimum fire fighting pump flow | 40L/S | |||||

| Minimum pressure | 1.0Mpa | |||||

| Flow (L/S) | Outlet pressure(Mpa) | Rated speed(r/min) |

Crank power (kw) | Suction depth(m) | ||

| 40 | 1 | 3080±50 | 62.92 | 3 | ||

| 28 | 1.3 | 3360±50 | 63.92 | 3 | ||

| 20 | 1 | 2990±50 | 41.95 | 7 | ||

| Fir fighting fixed water cannon in the top of truck | ||||||

| Diameter (mm) | φ100 | |||||

| Flow (L/min) | 40L/min | |||||

| Max range (m) | ≥ 65m | |||||

| Working pressure(Mpa) | ≤0.7 MPa | |||||

| Vertical rotation angle( degree) | -30~70 | |||||

| Horizontal rotation angle (degree) | 360 | |||||

| Size(mm) | 1000*340*600 | |||||

| Weight (kg) | ≤ 50 | |||||

| Pipe system | ||||||

| Pipe Line inlet | 2 inlet, φ125 inlet in the pump(our standard is 1 inlet) | |||||

| Pipe Line outlet | 2 outlet, φ65, in the back of pump | |||||

| Spraying water pump | ||||||

| Function | Control the front ,side and rear sprinkler | |||||

| Flow | 60m3/h | |||||

| Pump head | 90m | |||||

| Self-suction height | 6.5m | |||||

| Suction time | 1.5 (min/4m) | |||||

| Equipment | ||||||

| Fire electine siren | 1 Nos | |||||

| Emergency rotation lamp | 1-Nos | |||||

| Fire axe | 1-Nos | |||||

| Fire hook | 1-Nos(must be applied to climb) | |||||

| Fireman ladder(extension ladder ) | 1-Nos | |||||

| Jet&spray nozzle | 1-Nos | |||||

| Jet nozzle | 1-Nos | |||||

| Fire hoses(b/s system)(65mm, 20m) | 4-Nos | |||||

| Suction pipe (length 4m ) | 2-Nos | |||||

| Water filter(φ100,metal) and guide rope | 2-Nos | |||||

| Suction pipe wrench (100mm) | 2-Nos | |||||

| Fire hydrant wrench | 2-Nos | |||||

| Fire extinguisher(3kg) | 2-Nos | |||||

| Crane | Knuckle carne , telescopic crane | |||||

| No. | Main Items | Technical Parameters |

| 3.1 | Crane | |

| 3.1.1 | Brand | Optional |

| 3.1.2 | Model | Optional |

| 3.1.3 | Max. Lifting Weight | 5 Tons |

| 3.1.4 | Max. Working Weight | 10 Meters |

| 3.1.5 | Max. Operate Range | 8 Meters |

| 3.1.6 | Swivel angle | 370° |

| 3.1.7 | Installation Type | The rear of the vehicle and in the longitudinal centerline of the vehicle |

| 3.2 | Winch | |

| 3.2.1 | Brand | Optional |

| 3.2.2 | Model | Optional |

| 3.2.2 | Installation Type | Under the front bumper |

| 3.2.3 | Drive Type | Electric |

| 3.2.4 | Voltage | 24V |

| 3.2.5 | Max. Traction | 6118 Kgs |

| 3.2.6 | Max. Towing length | 38 meters |

| 3.3 | Generator | |

| 3.3.1 | Brand | Optional |

| 3.3.2 | Model | Optional |

| 3.3.3 | Drive Type | Gasoline Generator |

| 3.3.4 | Rated Power | 10 KvA |

| 3.3.5 | Rated Frequency | 50 Hz |

| 3.3.6 | Rated Voltage | 220 V |

| 3.3.7 | Location | In storage compartment |

| 3.4 | Telescopic Light | |

| 3.4.1 | Brand | Optional |

| 3.4.2 | Model | Optional |

| 3.4.3 | Power | 2x2000W |

| 3.4.4 | Lamp | Quartz halogen lamp |

| 3.4.5 | The Max. Height | 8 Meters from the ground |

| 3.4.6 | Rotation Angle | Horizontal:360° Pitch:120° |

| 3.4.7 | Working Voltage | 220V |

| 3.4.8 | Installation Type | On the top |

Emergency rescue fire truck training and use process (innovative version)

Three-dimensional advanced training system

1. Basic cognition of virtual and real combination

Holographic vehicle disassembly: Through the 3D dynamic model to display the internal structure of the fire truck, students can "see through" to observe the linkage principle of core components such as the engine, hydraulic system, and vehicle crane.

Risk sand table simulation: Use digital sand table to simulate different disaster scenarios (such as earthquake landslides and chemical explosions), so that students can predict the relationship between the parking position of the vehicle, the angle of the outriggers and the operating radius in a virtual environment.

2. Human-computer interaction skills training

Smart simulation cabin training: In the 1:1 simulation cockpit, students need to operate multiple screen terminals at the same time - the left hand adjusts the hydraulic pressure value, the right hand controls the telescopic trajectory of the boom, and the system generates mechanical feedback in real time (such as overload warning, wind speed resistance simulation).

AR assisted troubleshooting challenge: Wear augmented reality glasses to complete the troubleshooting task, the system randomly generates hidden problems such as "wire rope wear" and "oil line leakage", which tests students' detailed observation and emergency handling capabilities.

3. Practical training in extreme scenarios

Night blindness test: Turn off the lighting equipment and complete the hoisting positioning only with the dim light of the dashboard to enhance the spatial perception in the dark environment.

Cooperative combat drill: Set up the "golden 30 minutes" comprehensive rescue level, requiring team members to divide the work to operate fire trucks, demolition tools and life detectors, and realize the multi-threaded operation of "vehicle control + wounded transfer + fire suppression".

Dynamic ability evaluation system

Biological data monitoring: Capture the trainee's heart rate, muscle tension and other physiological indicators through smart bracelets to analyze the operational stability under high pressure.

Digital medal incentives: Unlock virtual achievements such as "Precision Hoisting Master" and "Extreme Environment Conqueror" according to the assessment performance, and generate a personal ability radar chart.

Lifelong skills preservation plan

Cloud case library update: Push the latest disaster rescue videos every month, combined with AI analysis technology points (such as the magnetic levitation fire truck operation module added in 2025).

Mobile micro-training: Complete the "5-minute daily" emergency micro-class through the mobile phone APP, such as the touch screen operation training of manually releasing the hydraulic lock when simulating a sudden power outage.

Features:

Advanced gamification: Design the training task as a "level-breaking mode", and unlock a higher difficulty skill tree after passing each level.

Metaverse collaboration: Support firefighters in multiple locations to enter the same virtual fire scene through VR equipment and conduct cross-regional joint drills.

Ecological feedback: Training data is automatically connected to the city's smart firefighting network to provide predictive suggestions for vehicle maintenance (such as intelligently prompting the replacement cycle of parts based on the frequency of use of the boom).

Training closed loop: From "cognition-muscle memory-conditioned reflex" progressive reinforcement, create a "super firefighter" who can accurately control equipment and have strategic thinking.